PRODUCT

صفحة رئيسية>منتجات>

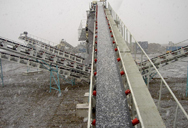

screening crushing of iron ore lumps into fines

Iron ore fines - BIMCO

Description: Iron ore fines come from the natural raw iron ore through the process of mining, crushing and screening, where the iron ore is separated into lumps and fines. Iron ore is done in this fashion so that it can be used for the iron/steel making industry.2022年1月1日 This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products. Low-grade hematite ores, on Comminution and classification technologies of iron oreSix steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing The six main steps of iron ore processing - Multotec

IRON ORE FINES

Large lumps as mined are crushed to approx 300mm. They are then further crushed to 6 – 40mm for shipment. Fines below 6mm can be further crushed and sold as sinter feed or But the lump and fines components will have different compositions, the lump usually being higher in iron and lower in other minerals. To estimate this lump to fines split, we need a Estimating the lump to fines composition split in iron ore productionWhat are Iron Ore Fines? Iron ore is a natural/raw material that is mined around the world. The material is processed to allow its use in the iron/ steel making industry. Initially, this on Or Ir e Fines - nepia

INTEGRATION OF IRON ORE DEPOSIT EVALUATION AND MINE

The sized ore produced from hard ore batch is with low moisture, high tumbler index (T.I.) and with low decrepitation index. The lump generated from friable ore batch, being high The transportation of iron ore fines has increased massively since the process of sintering – that is, coagulating iron ore fines with coke to enable their use in the blast furnace – The IMSBC Code 2013 - Nautical Institute2015年1月1日 Iron ore lumps (>16 mm) were processed in jig and log washers. •. Improved Fe content lead to a 20% increase in reserve volume. •. A geometallurgical Impact of quality of iron ore lumps on sustainability of mining ...

Relating Iron Ore Lump and Fines Grade Split to Ore Type - AusIMM

When iron ore is crushed and split into lump and fines components, there are systematic differences between the lump and fines grades. Generally the lump product is richer in

- ملمعات المطاحن

- سعر المحمولة الفك آلة محطم

- تجميع كسارة المجاميع في الصين

- تعدين الذهب ل حق الصخور

- شن و ماسه صفحه نمایش برق

- في كسارة الحفرة والمحمولة

- حزام مركز خام الحديد في مصر

- تعدين مصانع معالجة الأسمنت في الهند

- طحن الرصاص انقباض

- غربال للحجارة الذهب للبيع كسارة جنوب أفريقيا

- تعديل علبة التروس مطحنة ريموند

- سحق المورد مصنع في لاهور باكستان دراسة حالة

- مستعملة كسارات قياسي من الصين

- عملية تعدين تعدين الحديد مصر

- يمر عملية البوكسيت من التعدين إلى الألومينا

- قضبان التفجير للكسارات الصدمية

- فصل الأرضية النادرة في الصين

- دستگاه سنگ شکن ارائه شده است

- آلة تكسير المحجر

- vertical roller mill iron ore