PRODUCT

صفحة رئيسية>منتجات>

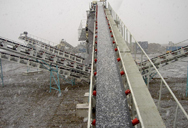

process of smelting iron ore

Smelting - Wikipedia

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, tin, lead and zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing ag2017年10月17日 The Hismelt process employs a single smelt reduction vessel (SRV) where iron oxide fines are injected deep into hot metal From Ore to Iron with Smelting and Direct Iron Smelting reduction employs two units: in the first, iron ore is heated and reduced by gases exiting from the second unit, which is a smelter-gasifier supplied with coal and oxygen. Iron processing - Smelting, Refining, Alloying Britannica

Iron Ore Smelting Process - Bright Hub Engineering

Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter. Here the ore is put Iron processing - Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are Iron processing - Ores, Smelting, Refining BritannicaGuide to Modern Smelting Processes – T09-002 5 Iron Smelting: Iron smelting involves reducing iron ore, typically hematite or magnetite, in a furnace. The high temperatures Guide to Modern Smelting Processes

Recent Trends in the Technologies of the Direct Reduction and

2023年4月5日 In a typical reduction-smelting process, the iron ore will first undergo a solid-state reduction in the pre-reduction unit. The resulting product is then smelted and Iron ores consist of oxygen and iron atoms bonded together into molecules. To convert it to metallic iron, it must be smelted or sent through a direct reduction process to remove Iron ore - Wikipedia2022年2月10日 1 Citations. Abstract. The hydrogen-based direct reduction of iron ore combined with EAF smelting is being widely discussed as a possible replacement for Circored Fine Ore Direct Reduction Plus DRI Smelting: Proven ...

- عملاء آلات التجفيف بنسلفانيا

- آلات تصنيع الرمل الاصطناعي من ألمانيا

- الفحم الفك محطم 600 الهيدروكربونات النفطية

- إثراء خام تصنيع مصنع

- عايزاشترى كسارة فوسفات

- آلة تكسير المحجر

- askaf iron ore design feasibility study

- الهيدروكربونات النفطية مجموع المباراتين عملية سحق

- مخروط محطم القياسية

- دستگاه سنگ شکن شن و ماسه

- الكسارات العالم شاشة الحصى

- المجلات على غرابيل الاهتزاز

- 50 طن لكل مطحنة الكرة ساعة

- المحمولة تأثير محطم الحجر الجيري للتأجير الهند

- الكتيبات طاحونة الأسطوانة العمودية

- المحورية كسارة اسطوانة البطانة السفلى

- الحجر الجيري الهيدروليكية ذات الصلة

- portable iron ore crusher price in south africa

- تكلفة الكسارة 10 tph

- طحن البنتونيت عملية الماكينات